Rail Inspection services

LMATS regularly undertake Rail Weld Joints inspection services using various inspection methods for the inspection of rail flash but welds and Aluminothermic welding "Thermite" procedures.

LMATS has ILAC MRA recognized accreditation pre-shipment inspections a product tested once and accepted everywhere

LMATS provides independent second line checks the manufacturer’s own inspection processes, carried out on either a second or third-party basis. This review not only ensures that the manufacturers are carrying out the correct checks and inspections but witnesses a sample set and identifies additional non-compliances or improvements throughout the process.

In-Service Rail Failures can have catastrophic effects on the bottom line whether it is from derailments causing large production losses to speed restrictions on the rail system

- 10% of joints are Aluminothermic welds

- 90% of joints are Flash Butt welds

- 90% of failures are in Aluminothermic welds

Majority of our work is qualification testing

In addition to inspection for mandatory compliance LMATS have many years of experience in the inspection of quality, finish and customer compliance issues, particularly final customer inspections.

{slider title="Rail Weld Ultrasonic Inspection" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix F and Table M2

{slider title="Rail Alignment" open="false" class="icon"}

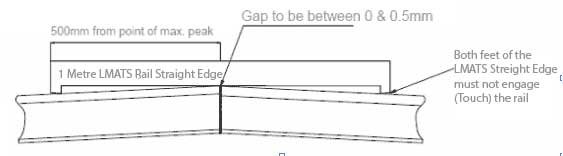

In accordance with AS 1085.20-2012, Appendix E and Table M2

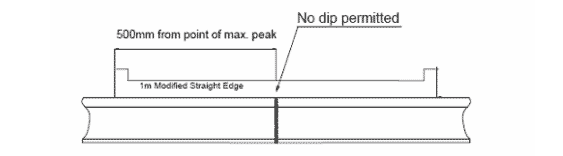

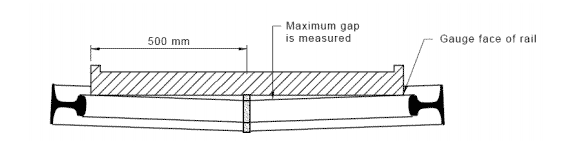

Surface Alignment (Top and Alignment)

{slider-Alignment title="Peaking" open="false" class="icon"}

{slider-Alignment title="Dipping" class="icon"}

{slider-Alignment title="Lateral" class="icon"}

The recorded value is the measured gap, This should usually be no more than 0.5mm

NOTE: For a curved track, the gap is not covered in this standard

{/sliders-Alignment}

{slider title="Rail Weld Head Hardness Testing" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix G and Tables M2, N3

Traverses conducted 5mm from the Railhead at 2mm indentation spacing in accordance with AS 1817.1 and AS 2205.6.1.

The Railhead hardness has a direct relationship to wear and the amount of Rolling contact fatigue (RCF)experienced. Rolling contact fatigue is the creation and development of cracks on the running surface of the rail due to contact stresses between the wheel and rail. The propagation of these cracks or fissures could lead to catastrophic rail failure.

{slider title="Rail Weld Macro (Macroscopic) and Microscopic Examination" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix H, I and Tables M2 and N3

Microstructure: & Martensite:

{slider title="Rail Weld Slow Bend Test" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix K and Table M2 and N3

{slider title="Rail weld Web Fatigue Test" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix L3

{slider title="Rail Weld Surface Visual Inspection" open="false" class="icon"}

- In accordance with AS 1085.20-2012, Appendix E and Table M2

Inspect the rail for visual signs of defects before the length is ultrasonically tested. The entire weld shall be inspected including the ground weld surface, the heat-affected

zone on both sides of the weld. Identify, record and report evidence (including size and position) of the following:

• Cracks

• Tears

• Gouges

• Gas porosity

• Shrinkage porosity

• Slag or sand inclusions

• Fins

• Electrode burns

• Grinding burns

• Hammer marks

• Abnormal heat-affected zone (HAZ) indications

• Riser break indicators (porosity, gas holes, etc)

• Bolt hole distance (bolt holes must be greater than 65mm from weld)

{slider title="Advanced Rail NDT Inspection Services" open="false" class="icon"}

LMATS offers advanced rail inspection availability on request.

{slider-advanced title="Rail Phased Array Ultrasonic Testing" open="false" class="icon"}

Rail Phased Array Ultrasonic Testing

Rail welding processes covered are flash butt welds in rails and Aluminothermic in accordance with the procedure to AS 1085.20-2012 and specifications to AS 1085.20-2012 Table F6.1

See Phased Array Ultrasonic testing

{slider-advanced title="Residual strain measurement" open="false" class="icon"}

Multiaxial Strain gauges are applied to the rail web and foot in line with the weld. A broach is then used to remove the material around the strain gauge while measuring the strain.

{slider-advanced title="Chemical analysis" open="false" class="icon"}

In accordance with AS 1085.20-2012, Appendix J and Table N3

By the method of Optical Emission Spectroscopy (OES)

See Optical Emission Spectroscopy (OES)

{/sliders-advanced}

{/sliders}

Want to know more about LMATS Rail Inspection Services and how we can assist you. Simply call us or contact us through our form